OUTSIDE: Maple sugar has a local history

Published 5:17 pm Wednesday, February 17, 2021

|

Getting your Trinity Audio player ready...

|

By Steve Roark

With maple syrup, the common assumption is that it’s a New England thing, produced in places like Vermont. But during European settlement times sugar made from maple sap was the only available sweeter besides honey. Early on land was cleared for growing food to survive on, not a luxury sweetener like molasses, and refined sugar from the West Indies was prohibitively expensive. But everyone who owned land had forests with maples, sugar maple in particular. And so the first sweetener produced in our region was maple sugar, and was valued not only for personal use but also as a sell-able farm product. In 1800 Daniel Boone and his wife Rebecca set up and made 400 pounds of maple sugar to sell or trade. This took several weeks to collect and boil down 2000 gallons of sugar maple sap.

The history of maple sugar goes back even before European settlement. Native Americans figured out that the sap of sugar maple could be collected and processed to make a sweetener. Their method of collection involved cutting horizontal notches in the bark and inserting a flat wooden wedge to direct sap into watertight collection baskets made of bark. The sap was then boiled down in clay pots. Another method was to put the sap in wooden bowls and allow it to freeze each night, discarding the ice that formed on the top each day. Since the suspended sugar does not go into the ice, the retained sap gradually gets sweeter. There’s not a lot of historical references that Native Americans used a lot of maple syrup or sugar, but they did flavor meat with it and also used it as a sweet beverage.

Like many things, the Indians introduced early settlers to maple sugar, and they in turn began making it. They eventually collected sap by drilling holes in the maple tree and inserting a wooden spout called a spile to collect the sap in wooden buckets. The sap was boiled down using iron kettles and a lot of firewood. A place that had a lot of sugar maples that could be used to tap and collect sap were referred to as a “sugar bush”, and camps that were established to collect and boil down sap were called “sugar camps”. Small cabins and sheds were often built because when the sap flow was high they had to work night and day to process it. Many local place names reflect the history of making maple syrup/sugar, such as Sugar Hollow, Sugar Run Creek, and Sugar Camp Lane.

By the mid-1800s cane sugar became more economically available and so making maple sugar gradually faded away except in New England, where the abundance of sugar maple trees and demand for maple syrup created a thriving farm industry. It is beginning to make a comeback in Kentucky and Virginia, where the Agricultural Extension Service is helping farmers diversify their farm income by making maple syrup. This makes sense since most farms have woodland acreage with maple trees, and syrup making is done in winter (January/February) when farmers have more down time.

I’ve dabbled with maple syrup and here are some particulars on making it small scale. Spouts or “taps” can be purchased made either of plastic or metal. A battery powered drill is perfect for drilling the 2” deep hole, and the sap can be collected in food safe buckets, sap bags, or on the cheap in plastic jugs with plastic tubing. The sap can be boiled down in constructed metal pans called evaporators like those used to make molasses. For small scale production you can use kitchen roasting pans that are shallow and provide a lot of surface area for more rapid evaporation of the sap. I have had success using aluminum foil pans over a wood fire. Another heat source to do the boil down is propane (as in turkey friar). The biggest requirement is time to boil down 40 gallons of sap to get a gallon of maple syrup. It’s an all-day deal, but man it’s good stuff.

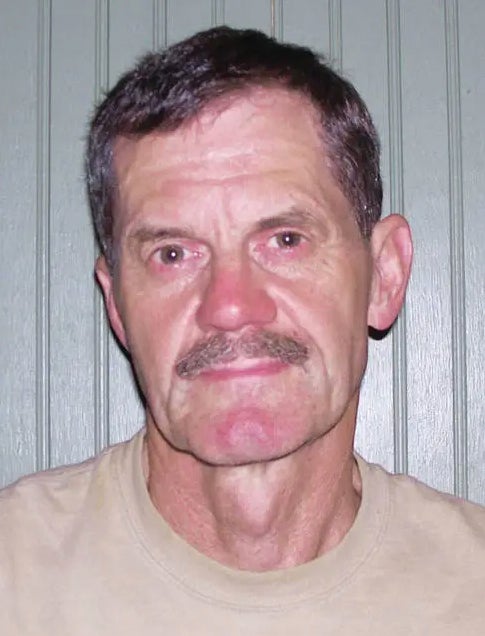

Steve Roark is a volunteer interpreter for the Cumberland Gap National Park.